- Home

- Information Technology

-

Chemical Manufacturing Software Market

Chemical Manufacturing Software Market by Software Type (Enterprise Resource Planning (ERP) Software, Product Lifecycle Management (PLM) Software, Quality Management Software, Others), Deployment (On Cloud, On Premises), Application (Large Enterprises, SMEs), and Region - Partner & Customer Ecosystem (Product Services, Proposition & Key Features) Competitive Index & Regional Footprints by MarketDigits - Forecast 2024-2032

Industry : Information Technology | Pages : 185 Pages | Published On : Apr 2024

Market Overview

The Chemical Manufacturing Software Market is experiencing robust growth, driven by increasing demand for efficient and streamlined operations within the chemical industry. The market is characterized by dynamic opportunities and challenges. Key drivers include the rising need for enhanced process automation, regulatory compliance, and the adoption of Industry 4.0 technologies. The market is poised for continuous expansion as chemical manufacturers seek solutions that optimize production processes, improve resource utilization, and ensure compliance with stringent safety and environmental standards. Additionally, the integration of advanced features like real-time monitoring, data analytics, and cloud-based solutions is expected to propel the market further.

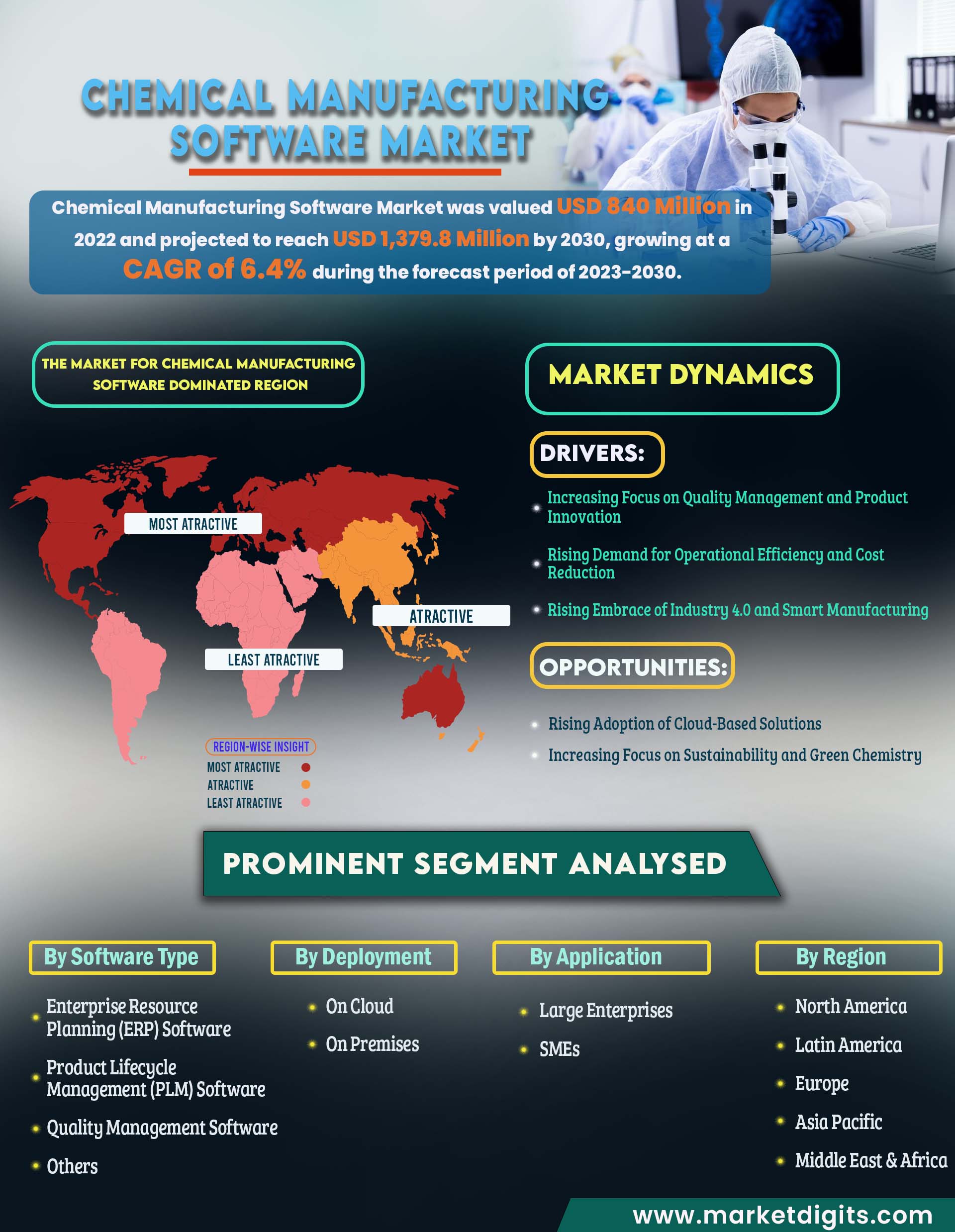

Chemical Manufacturing Software Market was valued USD 840 Million in 2022 and projected to reach USD 1,379.8 Million by 2030, growing at a CAGR of 6.4% during the forecast period of 2023-2030.

Major Players In Chemical Manufacturing Software Market Include: Aquilon ERP, Aspen Technology Inc, AVEVA , BatchMaster ERP, Dassault Systèmes, Datacor Chempax, Deskera ERP, Emerson Electric Co, GE DIGITAL, Honeywell International Inc, IFS Applications, Intellect eQMS, MasterControl Solutions, Inc,Odoo, QuickBooks Enterprise, Rockwell Automation, Royal 4 Systems, Sage Group plc, SAP SE, Vicinity Manufacturing and Others.

Growing Complexity in Supply Chain Management

The growing complexity in supply chain management has emerged as a significant driver for the Chemical Manufacturing Software Market. As the chemical industry expands globally, manufacturers are grappling with intricate supply chain networks that involve multiple stakeholders, diverse regulatory requirements, and intricate logistics. The need for real-time visibility, agility, and efficiency in managing the procurement of raw materials, production processes, and distribution channels has become paramount. Chemical manufacturing software addresses these challenges by providing robust solutions for supply chain optimization, demand forecasting, inventory management, and compliance tracking. By leveraging advanced analytics and automation, these software solutions empower companies to navigate the complexities of global supply chains more effectively, ensuring timely deliveries, minimizing risks, and enhancing overall operational efficiency. As the demand for streamlined supply chain processes continues to rise, the Chemical Manufacturing Software Market is well-positioned to grow as a critical enabler for the industry's sustainable and resilient operations.

Market Dynamics

Drivers:

- Increasing Focus on Quality Management and Product Innovation

- Rising Demand for Operational Efficiency and Cost Reduction

- Rising Embrace of Industry 4.0 and Smart Manufacturing

Opportunities:

- Rising Adoption of Cloud-Based Solutions

- Increasing Focus on Sustainability and Green Chemistry

Integration of Advanced Technologies

The Chemical Manufacturing Software Market is currently witnessing a notable trend towards the integration of advanced technologies, driving transformative changes within the industry. Industry 4.0 concepts, such as the Internet of Things (IoT), artificial intelligence, machine learning, and big data analytics, are being increasingly incorporated into software solutions for chemical manufacturing. These technologies offer unprecedented capabilities for real-time monitoring, predictive maintenance, and data-driven decision-making, revolutionizing traditional manufacturing processes. IoT sensors embedded in equipment provide valuable insights into production conditions, while AI and machine learning algorithms analyze vast datasets to optimize processes, detect anomalies, and enhance overall efficiency. This integration of advanced technologies not only improves operational efficiency but also enables proactive problem-solving and strategic planning. As chemical manufacturers recognize the potential of these innovations to drive competitiveness, the trend towards the integration of advanced technologies is expected to persist and define the future landscape of the Chemical Manufacturing Software Market.

The market for Chemical Manufacturing Software Market is dominated by North America.

North America is home to some of the largest chemical manufacturers in the world, such as Dow, DuPont, and BASF. These companies are early adopters of new technologies, and they invest heavily in chemical manufacturing software to improve their efficiency and productivity. North America has a favorable regulatory environment for the chemical industry. This includes clear and concise regulations, as well as government support for research and development. This creates a favorable environment for the development and adoption of chemical manufacturing software. North America is a leader in the adoption of new technologies, including digital technologies. This is due to a number of factors, including a high level of education, a strong culture of innovation, and a supportive government. The early adoption of new technologies has helped to drive the growth of the chemical manufacturing software market in North America.

Asia Pacific is the fastest-growing region for the chemical manufacturing software market. The chemical industry in Asia Pacific is growing rapidly, driven by urbanization, industrialization, and rising consumer demand. This is creating a growing demand for chemical manufacturing software solutions to help companies improve their efficiency and productivity. Governments in the Asia Pacific region are providing support for the development and adoption of chemical manufacturing software. This includes financial incentives, tax breaks, and research and development funding.

Local companies in the Asia Pacific region are partnering with foreign companies to develop and market chemical manufacturing software solutions. For example, in 2021, the Chinese company, AspenTech, partnered with the Japanese company, Yokogawa Electric Corporation, to develop and market chemical manufacturing software solutions in the Asia Pacific region. In 2023, the Chinese company, Hangzhou Hikvision Digital Technology Co., Ltd., launched a new chemical manufacturing software solution called “Hikvision Chemical Manufacturing Management System." The software is designed to help chemical companies improve their efficiency and productivity.

On Cloud Segment is Anticipated to Hold the Largest Market Share During the Forecast Period

Based on by deployment segment the chemical manufacturing software segment is categorized into on Cloud and on premises. Among the deployment segment the on cloud based segment has major share in chemical manufacturing software market. Cloud-based software solutions can be easily scaled up or down to meet the changing needs of a chemical company. This is important for chemical companies, which often experience seasonal fluctuations in demand. Cloud-based software solutions are typically more affordable than on-premises software solutions. This is because chemical companies do not have to invest in and maintain their own servers and hardware. Cloud-based software solutions are easy to use and implement. Chemical companies can typically start using cloud-based software solutions within a few weeks or months, compared to months or years for on-premises software solutions.

Segmentations Analysis of Chemical Manufacturing Software Market: -

- By Software Type

- Enterprise Resource Planning (ERP) Software

- Product Lifecycle Management (PLM) Software

- Quality Management Software

- Others

- By Deployment

- On Cloud

- On Premises

- By Application

- Large Enterprises

- SMEs

- By Region

- North America

- US

- Canada

- Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Chile

- Peru

- Rest of Latin America

- Europe

- Germany

- France

- Italy

- Spain

- U.K.

- BENELUX

- CIS & Russia

- Nordics

- Austria

- Poland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Thailand

- Indonesia

- Malaysia

- Vietnam

- Australia & New Zealand

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Nigeria

- Egypt

- Israel

- Turkey

- Rest of MEA

- North America

Recent Developments

- In 2023, Siemens launched a new cloud-based chemical manufacturing software solution called "Simcenter STAR-CCM+ Cloud." The software is designed to help chemical companies simulate and optimize their manufacturing processes in the cloud.

- In 2022, AspenTech launched a new AI-powered chemical manufacturing software solution called "AspenONE Process Explorer." The software is designed to help chemical companies identify and optimize process bottlenecks and inefficiencies.

Answers to Following Key Questions:

- What will be the Chemical Manufacturing Software Market’s Trends & growth rate? What analysis has been done of the prices, sales, and volume of the top producers of Chemical Manufacturing Software Market?

- What are the main forces behind worldwide Chemical Manufacturing Software Market? Which companies dominate Chemical Manufacturing Software Market?

- Which companies dominate Chemical Manufacturing Software Market? Which business possibilities, dangers, and tactics did they embrace in the market?

- What are the global Insight Engines industry's suppliers' opportunities and dangers in Chemical Manufacturing Software Market?

- What is the Insight Engines industry's regional sales, income, and pricing analysis? In the Chemical Manufacturing Software Market, who are the distributors, traders, and resellers?

- What are the main geographic areas for various trades that are anticipated to have astounding expansion over the Chemical Manufacturing Software Market?

- What are the main geographical areas for various industries that are anticipated to observe astounding expansion for Chemical Manufacturing Software Market?

- What are the dominant revenue-generating regions for Chemical Manufacturing Software Market, as well as regional growth trends?

- By the end of the forecast period, what will the market size and growth rate be?

- What are the main Chemical Manufacturing Software Market trends that are influencing the market's expansion?

- Which key product categories dominate Chemical Manufacturing Software Market? What is Chemical Manufacturing Software Market’s main applications?

- In the coming years, which Chemical Manufacturing Software Market technology will dominate the market?

Reason to purchase this Chemical Manufacturing Software Market Report:

- Determine prospective investment areas based on a detailed trend analysis of the global Chemical Manufacturing Software Market over the next years.

- Gain an in-depth understanding of the underlying factors driving demand for different Chemical Manufacturing Software Market segments in the top spending countries across the world and identify the opportunities each offers.

- Strengthen your understanding of the market in terms of demand drivers, industry trends, and the latest technological developments, among others.

- Identify the major channels that are driving the global Chemical Manufacturing Software Market, providing a clear picture of future opportunities that can be tapped, resulting in revenue expansion.

- Channelize resources by focusing on the ongoing programs that are being undertaken by the different countries within the global Chemical Manufacturing Software Market.

- Make correct business decisions based on a thorough analysis of the total competitive landscape of the sector with detailed profiles of the top Chemical Manufacturing Software Market providers worldwide, including information about their products, alliances, recent contract wins, and financial analysis wherever available.

TOC

Table and Figures

Methodology:

At MarketDigits, we take immense pride in our 360° Research Methodology, which serves as the cornerstone of our research process. It represents a rigorous and comprehensive approach that goes beyond traditional methods to provide a holistic understanding of industry dynamics.

This methodology is built upon the integration of all seven research methodologies developed by MarketDigits, a renowned global research and consulting firm. By leveraging the collective strength of these methodologies, we are able to deliver a 360° view of the challenges, trends, and issues impacting your industry.

The first step of our 360° Research Methodology™ involves conducting extensive primary research, which involves gathering first-hand information through interviews, surveys, and interactions with industry experts, key stakeholders, and market participants. This approach enables us to gather valuable insights and perspectives directly from the source.

Secondary research is another crucial component of our methodology. It involves a deep dive into various data sources, including industry reports, market databases, scholarly articles, and regulatory documents. This helps us gather a wide range of information, validate findings, and provide a comprehensive understanding of the industry landscape.

Furthermore, our methodology incorporates technology-based research techniques, such as data mining, text analytics, and predictive modelling, to uncover hidden patterns, correlations, and trends within the data. This data-driven approach enhances the accuracy and reliability of our analysis, enabling us to make informed and actionable recommendations.

In addition, our analysts bring their industry expertise and domain knowledge to bear on the research process. Their deep understanding of market dynamics, emerging trends, and future prospects allows for insightful interpretation of the data and identification of strategic opportunities.

To ensure the highest level of quality and reliability, our research process undergoes rigorous validation and verification. This includes cross-referencing and triangulation of data from multiple sources, as well as peer reviews and expert consultations.

The result of our 360° Research Methodology is a comprehensive and robust research report that empowers you to make well-informed business decisions. It provides a panoramic view of the industry landscape, helping you navigate challenges, seize opportunities, and stay ahead of the competition.

In summary, our 360° Research Methodology is designed to provide you with a deep understanding of your industry by integrating various research techniques, industry expertise, and data-driven analysis. It ensures that every business decision you make is based on a well-triangulated and comprehensive research experience.

• Product Planning Strategy

• New Product Stratergy

• Expanded Research Scope

• Comprehensive Research

• Strategic Consulting

• Provocative and pragmatic

• Accelerate Revenue & Growth

• Evaluate the competitive landscape

• Optimize your partner network

• Analyzing industries

• Mapping trends

• Strategizing growth

• Implementing plans

Covered Key Topics

Growth Opportunities

Market Growth Drivers

Leading Market Players

Company Market Share

Market Size and Growth Rate

Market Trend and Technological

Research Assistance

We will be happy to help you find what you need. Please call us or write to us:

+1 510-730-3200 (USA Number)

Email: sales@marketdigits.com